Innovative & Experienced

PVI Technology manufactures thermal diffusion systems, thin film deposition systems, heated tube assemblies, and high-temperature vacuum processing equipment for demanding applications, including:

- Photovoltaics

- Flat-panel display

- Semi-conductors

- Aerospace

Custom Built, Dedicated Support

- Leading-edge engineering

- Superior manufacturing

- High-quality workmanship

- Complete turnkey solutions

- World-class support

Ready to find out what we can build for you?

Let us know your project specs

OUR PRODUCT LINE

Innovative Technology You Can Depend On

QRV - 100/200

Quartz Furnace

The quartz vacuum furnace consisting of a split tube furnace and a quartz tube configured with stainless steel collars at each end of the tube. Gas inlet and pressure monitoring are provided on one end and gas exhaust at the other end of the tube. This configuration allows the substrates to be heated in a vacuum or with gas flowing. The furnace has three, split heater zones for control of the top and bottom heater elements.

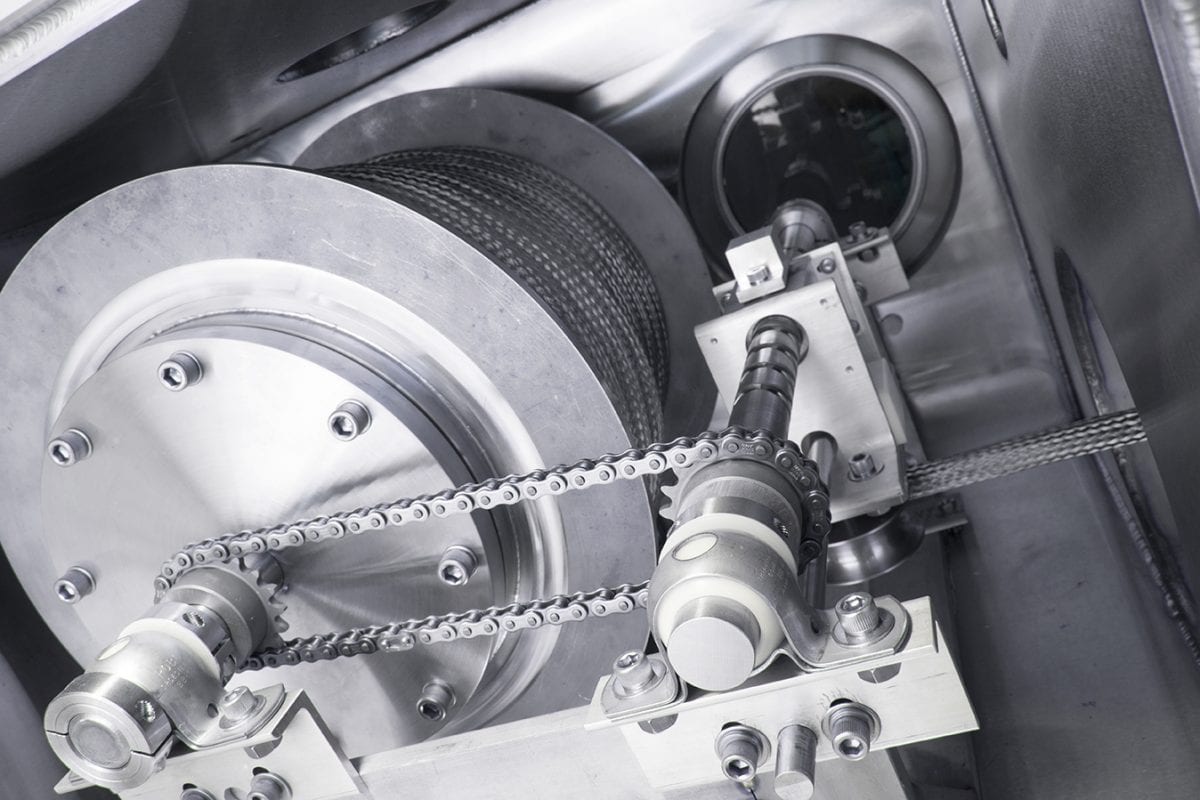

HWRF FURNACE

HOT WALL RETORT FURNACE

Dual-ended horizontal, cylindrical vacuum chamber, high degree of reliability, safety and flexibility, 20 hot zones with independent thermocouples, operating temperatures up to 1000˚C, 2-axis sliding door assembly, limit switches, all required ports for pressure monitoring, process gas flow, pumping, temperature measurement, venting, and auxiliary purposes.

SAS - 100

GEN 3.5 FURNACE

The SAS-100 Gen 3.5 thermal diffusion system contains a horizontal process chamber fabricated from opaque Quartz. The SAS-100 Gen 3.5 system is designed and manufactured to have a high degree of reliability, safety, and flexibility for future system modifications. Heater zones can be configured as per customer requirements.

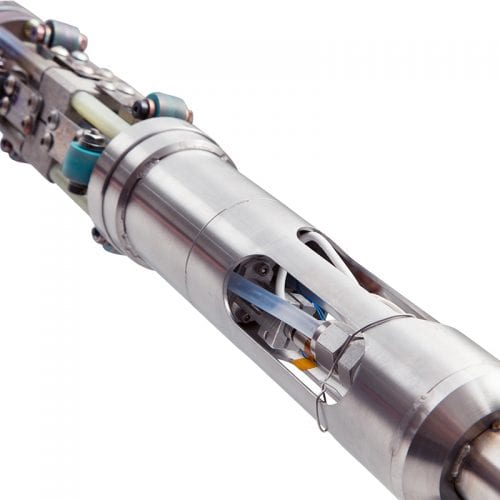

CYLINDRICAL

MAGNETRON

Precise, controlled tube cleaning and coating. Applications include coating accelerator beam tubes with thin films including crystalline Cu, Nb, Au, a-C films and other materials.